Customer Story

PSG/ProAmpac

Location: USA

Website: psglabels.com

Download a PDF of the story.

“This is an awesome tool, wish we had it years ago. It will catch any discrepancies between printed samples and artwork proof.”

Vincent Maltese, Quality Assurance Manager, PSG/ProAmpac Franklin Park

How PSG/ProAmpac Ensures the Quality and Accuracy of Their Packaging & Labelling

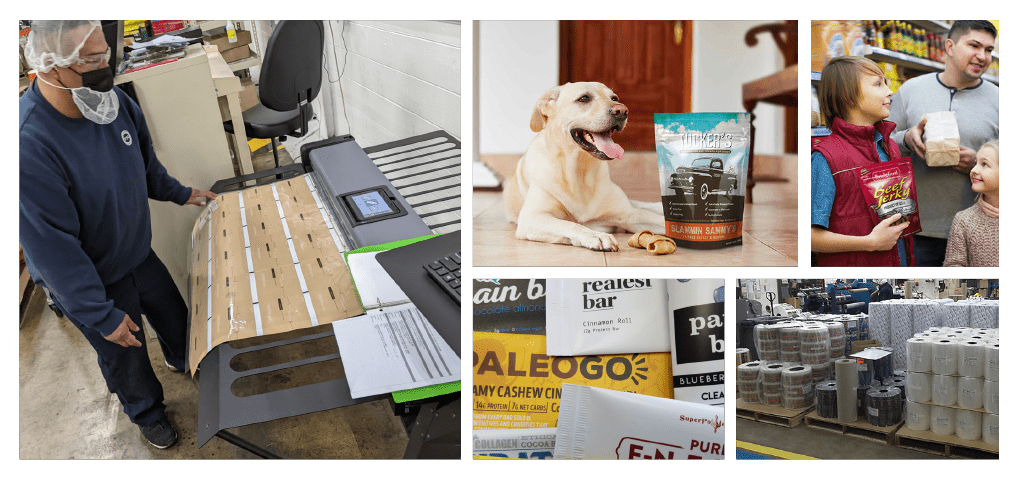

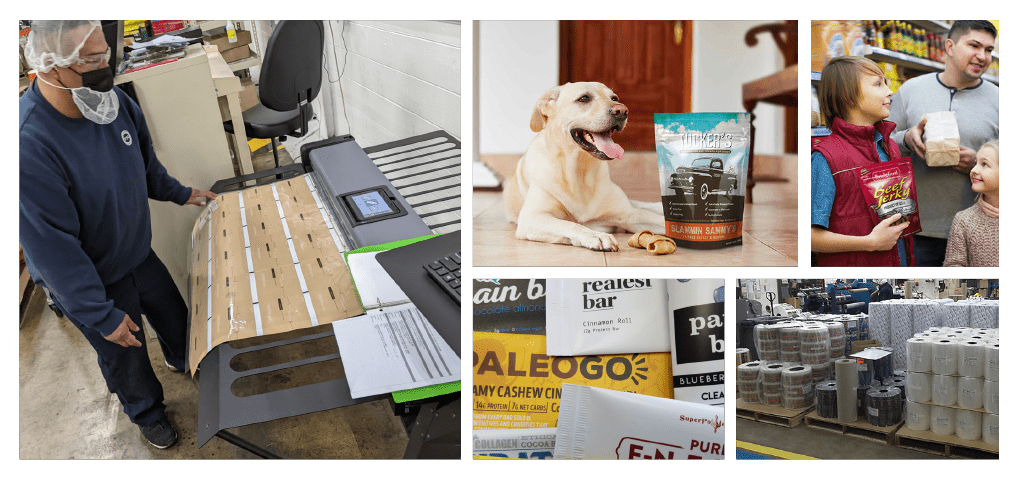

Prairie State Group (PSG) is an SQF-certified provider of flexible packaging and labeling services. They produce a wide range of sustainable, flexible packaging for the food and pet food industry and also offer label solutions. Their services include wrappers, pouches, compostable film, roll stock, and pressure-sensitive labels.

In December 2021, PSG was acquired by ProAmpac, a leading global flexible packaging company, to strengthen its labeling capabilities and expand its presence in the food and pet food markets. This acquisition and partnership also confirmed their leading position in the industry and will allow for further expansion and innovation, enabling both companies to serve a broader customer base with high-quality, specialized products.

ProAmpac has nearly 50 sites globally, with over 6,000 employees supplying over 5,000 customers in 90 countries.

Overview

Due to the highly specialized nature of its products and services, PSG/ProAmpac has to ensure the utmost quality of its packaging and labeling. Errors or mistakes in copy or artwork could lead to detrimental recalls, financial losses, or a decrease in brand loyalty and integrity – all issues that could otherwise be very difficult to reverse.

To ensure their products’ quality, accuracy, and consistency, PSG/ProAmpac turned to GlobalVision as the solution to their inspection and verification problems.

“There was a skip in the adhesive, and GlobalVision caught it. Same with typo errors if that was to be missing type”

Cris Sosa, Shift Supervisor/Press Operator, PSG/ProAmpac Franklin Park

Approach

After years of working with GlobalVision’s prepress software to help inspect their digital files, PSG/ProAmpac saw a great need for their solutions on their production floor to help inspect printed sheets to PDF files. They were noticing regular issues such as printed defects, smashes, registration, and sometimes content and graphic errors.

GlobalVision’s R44 printers and inspection system were therefore introduced to find differences and discrepancies in content with the utmost accuracy ensuring product and brand perfection. The implementation led to:

GlobalVision’s R44 printers and inspection system were therefore introduced to find differences and discrepancies in content with the utmost accuracy ensuring product and brand perfection. The implementation led to:

- Faster production times by switching from manual to automated solutions

- Finding all critical errors in content, no matter how small

- Assuring the utmost quality and accuracy of products

- Improving communication with PDF saved reports that are shared internally or externally with customers

Conclusion

With the implementation of GlobalVision’s quality control inspection system, PSG/ProAmpac was able to fully automate its inspection and verification processes while also automating all known gaps for quality control checks. Due to the diligence of GlobalVision’s support team and the innovative solutions offered by the inspection system, PSG/ProAmpac has been a satisfied partner since 2018 and has been producing error-free products and content ever since.

“It’s really great to have something like this to reinforce brand protection. It gives our customers peace of mind that we’re going the extra mile to ensure the integrity of what we print.”

Dan Doherty, Executive VP of Operations, PSG/ProAmpac Franklin Park

“This is an awesome tool, wish we had it years ago. It will catch any discrepancies between printed samples and artwork proof.”

Vincent Maltese, Quality Assurance Manager, PSG/ProAmpac Franklin Park

How PSG/ProAmpac Ensures the Quality and Accuracy of Their Packaging & Labelling

Prairie State Group (PSG) is an SQF-certified provider of flexible packaging and labeling services. They produce a wide range of sustainable, flexible packaging for the food and pet food industry and also offer label solutions. Their services include wrappers, pouches, compostable film, roll stock, and pressure-sensitive labels.

In December 2021, PSG was acquired by ProAmpac, a leading global flexible packaging company, to strengthen its labeling capabilities and expand its presence in the food and pet food markets. This acquisition and partnership also confirmed their leading position in the industry and will allow for further expansion and innovation, enabling both companies to serve a broader customer base with high-quality, specialized products.

ProAmpac has nearly 50 sites globally, with over 6,000 employees supplying over 5,000 customers in 90 countries.

Overview

Due to the highly specialized nature of its products and services, PSG/ProAmpac has to ensure the utmost quality of its packaging and labeling. Errors or mistakes in copy or artwork could lead to detrimental recalls, financial losses, or a decrease in brand loyalty and integrity – all issues that could otherwise be very difficult to reverse.

To ensure their products’ quality, accuracy, and consistency, PSG/ProAmpac turned to GlobalVision as the solution to their inspection and verification problems.

“There was a skip in the adhesive, and GlobalVision caught it. Same with typo errors if that was to be missing type”

Cris Sosa, Shift Supervisor/Press Operator, PSG/ProAmpac Franklin Park

Approach

After years of working with GlobalVision’s prepress software to help inspect their digital files, PSG/ProAmpac saw a great need for their solutions on their production floor to help inspect printed sheets to PDF files. They were noticing regular issues such as printed defects, smashes, registration, and sometimes content and graphic errors.

GlobalVision’s R44 printers and inspection system were therefore introduced to find differences and discrepancies in content with the utmost accuracy ensuring product and brand perfection. The implementation led to:

GlobalVision’s R44 printers and inspection system were therefore introduced to find differences and discrepancies in content with the utmost accuracy ensuring product and brand perfection. The implementation led to:

- Faster production times by switching from manual to automated solutions

- Finding all critical errors in content, no matter how small

- Assuring the utmost quality and accuracy of products

- Improving communication with PDF saved reports that are shared internally or externally with customers

Conclusion

With the implementation of GlobalVision’s quality control inspection system, PSG/ProAmpac was able to fully automate its inspection and verification processes while also automating all known gaps for quality control checks. Due to the diligence of GlobalVision’s support team and the innovative solutions offered by the inspection system, PSG/ProAmpac has been a satisfied partner since 2018 and has been producing error-free products and content ever since.

“It’s really great to have something like this to reinforce brand protection. It gives our customers peace of mind that we’re going the extra mile to ensure the integrity of what we print.”

Dan Doherty, Executive VP of Operations, PSG/ProAmpac Franklin Park

Recommended Readings

Recommended Readings

GUIDES

The 5 Most Common Printed Packaging Errors

This guide will explore the common sources of errors that can be found on the printer’s proof, approved text copy, barcodes, and printed components..